Traditionally, a Warehouse Control System (WCS) executes instructions provided by an upper-level host system, such as an ERP system or a WMS system. QC Enterprise used at the Arbonne International facilities, on the other hand, is a true Tier 1 WCS which provides advanced management capabilities including inventory control, resource scheduling, and order management.

Arbonne International, the leading network marketing health and wellness firm, just introduced (January 2010) Figure 8 Healthy Living & Weight Loss Program Ready to Drink Go Easy! Chocolate Protein Shakes. Previously the product was only available in a powder mix. (The shake is also available in a vanilla flavor; as a weight-lifter they taste great and provide 20 grams of protein per shake.)

The protein sources are vegetarian consisting of Pea Protein Isolate, Cranberry Protein, and Rice Protein. As baby-boomers fight the battle of the bulge, this type of product is becoming increasingly popular. The health advantages are clear: more than 20 essential vitamins and minerals, plus flaxseed, this new SKU represents a delicious, convenient, and satisfying drink helps athletes (and would be athletes) feel fuller longer with three sources of protein; it helps increase energy and provides 20g of protein. Formulated vegan, this shake has no saturated or trans-fats, cholesterol, artificial sweeteners, flavors or colors.

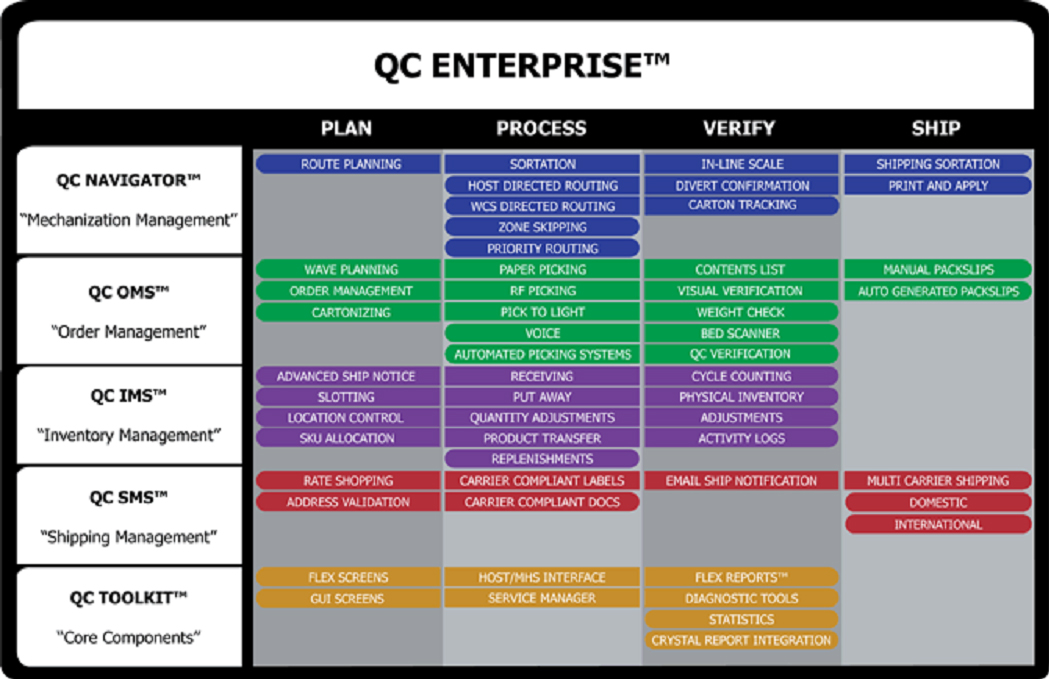

Introducing the new product did not present a challenge to the warehouses in Irvine, California or Greenwood, Indiana because the warehouse control system used is a suite of integrated software products that encompasses all of the tools necessary to efficiently and economically operate a warehouse or distribution center.

QC Software, through extensive research, development and rigorous testing, has developed a modular system which was easily configurable, platform independent, and with a scalable architecture, to satisfy the needs of any size warehouse, which has been critical as Arbonne has experience significant growth every year for the past decade.

The functionality that Arbonne is able to use with 450 products is shown below:

Warehouse Control Systems (WCS) often require proof of concept according to Jerry List, vice president of QC Software. Management teams in direct-to-consumer distribution centers usually turn to improved warehouse technology solutions when one of two circumstances occurs: rapid growth requiring improved throughput capacity or serious quality-control issues (such as “mispicks” or error-prone shipping). Both these challenges will produce lower customer satisfaction if the correct products are not received in a timely manner.

These issues often arrive on the desks of senior managers via warehouse floor managers or quality assurance personnel. The inability to keep up with demand sounds an alarm. These shipments are not usually pallets of single SKU’s, in which case a vanilla WMS — warehouse management system, is often sufficient. Individual cartons packed with various items require efficient pick and pack processes. “Moving away from paper-based picking toward RF (radio frequency bar-coded) picking directly to cartons is an initial signal that WCS may be in order,” List suggests. High-volume conveyors installed with scales allow tolerance weights to be established and reduce the need to individually verify cartons.

Arbonne’s products, based on herbal and botanical principles, are shared worldwide by the company’s network of independent consultants. The product line has since grown to include a comprehensive line nutrition and weight-loss products, including the new Ready to Drink Go Easy! Protein shakes.

Richard Estalella, senior vice president at Arbonne, shared that there has been a natural progression to the warehouse control systems that is used in Irvine, California, then Greenwood, Indiana, and now in Calgary and Toronto. Estalella explained the progression, “Most distribution centers start as manual picks until volume grows and automation is needed because the head count has “maxed out.” With rapid growth the choice is either to increase head count to achieve fulfillment or automate. The first round of automation in our Irvine distribution centre involved conveyors, carton flow, order entry fulfillment...pick, pack, and ship.”

In March 2010, the company is scheduled to introduce another 150 new products, although new CEO Kay Napier was tight-lipped at a recent West Palm Beach event about exactly how many of these new items will be in the food and nutrition arena. The company is clearly confident that the QC Software WCS technology solution is scalable and fully equipped to handle to introduction of all the new SKU without delaying shipments to either consultants or preferred clients.

Thomas R. Cutler is the President & CEO of Fort Lauderdale, Florida-based, TR Cutler, Inc, (www.trcutlerinc.com). Cutler is the founder of the Manufacturing Media Consortium of three thousand five hundred journalists and editors writing about trends in manufacturing. Cutler is a member of the Society of Professional Journalists, Online News Association, American Society of Business Publication Editors, Committee of Concerned Journalists, as well as author of more than 300 feature articles annually regarding the manufacturing sector. Cutler is also the developer of lean technology C.E.O (Continuous Experiential Optimization). Cutler can be contacted at

trcutler@trcutlerinc.com